INLINER - RENOVATION

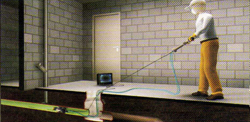

For repairing damaged sewer pipes and limited service lines offerLet's loose reconstruction of the grave liners .

For small damage such as joint displacement , einragenden seals , external water inlet or

also growing roots often enough to fit a short liner ( partliner ) .

For longer cracks or damage on several long distance Long liners are used .

With a remote cutting robot , the terminals after hardening again

milled . High-quality, field-tested fabric materials and resins , as well as our trained

Personnel to assure a high quality of our work .

LONG LINER RESTORATION

|

|

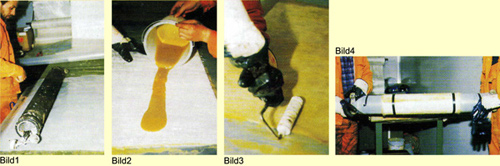

| 1 The Bravo liner is to the required length cut and the two Components & ( Resin and hardener) are mixed . |

2 The epoxy mixture is in the liner filled and by calibrating in this spread . |

|

|

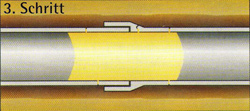

| 3 With the Brawoliner ( inversion drum) the impregnated liner with compressed air into the damaged pipe installed . Curing can be accelerated with warm water. |

4 The previously closed by the Linder A runs are using a small cutter , the RS cutter now milled . |

liner renovation technology - impressive benefits

- No digging , no spraying of walls or floors

- No construction noise, no dust emissions

- low space requirement - no interference vpn residents , MLS Pedestrians and business operations

- Excellent price - performance ratio , MLS

Low material cost , long life expectancy

the rehabilitated pipe - RAL quality mark / DIBT

SHORT LINER RESTORATION

In the dimensions (average) 70-300 can circular cross -sections of concrete, reinforced concrete , fiber cement , MLS Cast iron , fiberglass and stoneware to be repaired.

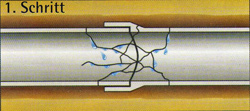

The damaged area must be precisely measured in advance and using high pressure cleaning or for cleaning

smooth-walled pipes ( eg stoneware) by mechanical cleaning ( milling, grinding ) with

subsequent high -pressure cleaning are preparing : Photos

Corresponding to the inner diameter of the channel and the requirements relevaten

Konudur glass sandwich mat cut to 975 ( Fig. 1).

The lift bubbles mixed and homogeneously colored mixture of epoxy resin and hardener

is uniformly and quickly incorporated into the glass fiber mat bzw.laminiert (Figs. 2 and 3).

The treat with resin glass fiber mat is then sized according to one, with

Release film and release agents provided packer 2-4 ply in a minimum wall thickness of Madame Applied 3mm and fixed ( Fig. 4).

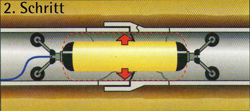

Then again , the packer positioned on the damaged area to be repaired and pressure

expanded air, so that the impregnated glass fiber mat on the inner wall frictionally

the damaged pipe is pressed . Here, excess resin is scheduled

pressed into the damaged area , by the intrusion of reaction resin into the cracks and joints

column is usually about the pure bond also additionally a physical

Clawing of partliner to the old pipe instead .

damaged pipe sleeve | |

Damaged area after repair |

Using flow packers can a costly drainage usually be waived. Through various resin types / - Additives achieve a practical cure. A final pressure test conducted confirms the tightness of the built-in short liner . |